Water purity is critical in modern industrial production and everyday life. From the manufacture of sophisticated electronic components to the production of health-critical food and beverages, high purity water is a key factor in ensuring product quality and the normal operation of equipment. Mixed-bed resins, with their unique properties and highly efficient ion exchange capabilities, have become an important solution for realizing high-purity water. In this article, we will discuss in depth the characteristics and working principle of mixed-bed resins and their wide range of applications in a number of industries.

What Are Mixed Bed Resins?

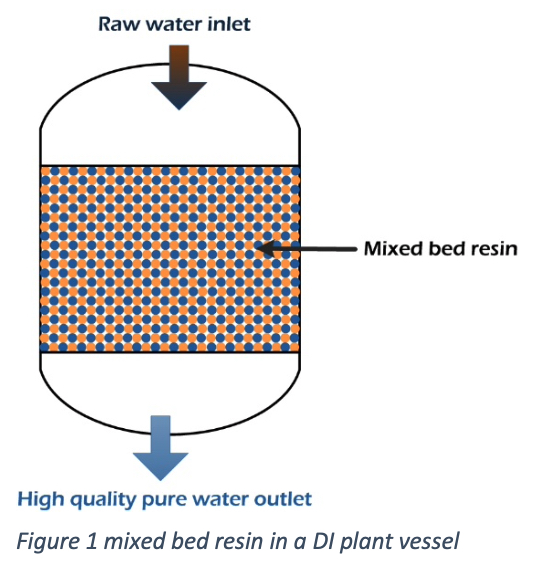

Mixed bed resins are ion exchange media consisting of a 2:3 ratio of strong acid cation resin and strong base anion resin. Unlike traditional deionization equipment, which uses two separate resin beds, one containing a cationic resin bed and the other containing an anionic resin bed, mixed-bed resin mixes two different ion exchange resins in a single container to form a single resin bed.

Ion exchange resins exist in many forms and function in different application scenarios. For example, softening resins, usually in the form of Na⁺, are mainly used to remove calcium and magnesium ions from water and reduce water hardness, while cation resins used for deionization are in the form of H⁺, which is capable of exchanging with cations in water.

How Mixed Bed Resins Work

The efficient operation of the Mixed Bed Resin relies on its unique dual-resin composition, which allows it to accomplish full ion exchange in a single pass, enabling the preparation of high-purity water.

Ion Attraction: As water passes through the Mixed Bed Resin, positively charged cations in the water are attracted to the cation resin beads, while negatively charged anions are attracted to the anion resin beads. This process is based on the interaction of charges, and like a magnet attracting iron filings, the resin creates a strong attraction for ions of the corresponding charge.

Ion Exchange Reaction: While attracting ions, the resin exchanges its own hydrogen ions (H⁺) and hydroxide ions (OH-) with the impurity ions in the water. Through this exchange, the impurity ions in the water are removed, while the H⁺ and OH- ions combine to form pure water molecules (H₂O).

Continuous Purification: Due to the synergistic action of the anionic and cationic resins in the Mixed Bed Resin, it continuously removes both cations and anions from the water, achieving highly efficient ion removal. This dual-resin characteristic enables the Mixed Bed Resin to achieve a level of ion removal far beyond that which can be achieved by using the cation and anion beds alone, yielding ultra-high purity water.

Wide Application Of Mixed-Bed Resins In Ten Major Industries

Power Plants

In the field of power production, the quality of water is directly related to the service life of equipment and the efficiency of power generation. Mixed-bed resins play an indispensable role in power plants.

Boiler Feed Water Treatment: When used in the production of boiler feed water, mixed-bed resin can effectively remove various ions in the water and prevent the formation of scale inside the boiler. The presence of scale reduces the heat transfer efficiency of the boiler, increases energy consumption, and may even lead to clogged piping and equipment damage. By using ultrapure water prepared with mixed-bed resin as boiler feed water, the formation of scale can be greatly reduced, ensuring the safe and stable operation of the boiler.

Steam Turbine Systems: In steam turbine systems, any impurities can cause serious damage to the equipment. The high purity water produced by the mixed bed resin ensures the quality of the steam and avoids problems such as blade corrosion and abrasion caused by impurities in the water, thus improving the operating efficiency and reliability of the steam turbine.

Electronics Manufacturing

Semiconductor and electronic component manufacturing requires extremely high water quality, even a trace amount of ionic impurities may affect the performance and yield of the chip. Mixed bed resins play a key role in the electronics manufacturing industry.

Cleaning, etching and rinsing: In the production of electronic components, large quantities of ultrapure water are required for cleaning, etching and rinsing chips and other components. Mixed-bed resins can effectively remove a variety of ionic contaminants in the water to ensure that the cleaning process will not introduce new impurities, thus ensuring the accuracy and performance of electronic components.

Microchip Manufacturing and Device Assembly: For microchip manufacturing and device assembly, the stability and purity of water quality is critical. Mixed-bed resins provide ultrapure water to meet the needs of these high-precision processes, helping to produce electronics with superior performance and reliable quality.

Pharmaceutical Industry

Pharmaceutical production must comply with strict regulations and standards, and the water quality requirements are nearly as demanding. Mixed-bed resins are an important means of safeguarding water quality in the pharmaceutical industry.

Pharmaceutical Formulation: Water is an important part of many pharmaceutical formulations in the development and production of drugs. The use of high purity water treated with mixed bed resins ensures the stability and potency of drug ingredients and avoids drug quality problems caused by impurities in the water.

Cleaning and Sterilization Systems: In the cleaning and sterilization systems of pharmaceutical plants, deionized water prepared from mixed-bed resins is used for the cleaning of equipment and piping and the maintenance of a sterile environment. This helps prevent microbial contamination and ensures the safety and compliance of the pharmaceutical manufacturing process.

Food and Beverage Industry

The quality of food and beverages is linked to the health of consumers, and the quality of water, a key ingredient in the production process, is critical. Mixed bed resins play an important role in the food and beverage industry.

Taste Enhancement: Salts and ions in water affect the taste of food and beverages. The removal of these impurities through mixed bed resins results in a purer, more refreshing product that enhances the consumer's drinking experience.

Safety And Security: Mixed bed resins can ensure that the water used in production meets strict safety and hygiene standards, preventing food contamination and safety accidents caused by water quality problems and safeguarding consumers' health.

Laboratories and Research Organizations

In scientific research and experimental processes, the purity of water has a direct impact on the accuracy and reliability of experimental results. Mixed bed resins provide a reliable water quality guarantee for laboratories and research institutes.

Sensitive Experiments: For many sensitive chemical and biological experiments, ionic impurities in the water may interfere with the experimental reactions, leading to deviations in the experimental results. The ultrapure water prepared by mixed-bed resin can meet the strict water quality requirements of these experiments and ensure the accuracy and reproducibility of the experimental results.

Laboratory Equipment: Many equipment in the laboratory, such as autoclaves, spectrophotometers and various analyzers, etc., all need to use high-purity water for normal operation. The stable water quality provided by mixed-bed resins extends the life of the equipment and ensures the accuracy of experimental data.

Chemical Manufacturing

During chemical synthesis, the presence of ions may interfere with the chemical reaction, affecting product quality and yield. Mixed bed resins play an important role in the chemical manufacturing industry.

Water for Formulation: Ensuring that the water used in the chemical synthesis process is of a consistent quality ensures that chemical reactions are stable and reproducible, thereby improving product quality and productivity.

Contamination Control: By removing ionic impurities from the water, mixed-bed resins reduce the risk of contamination in high-purity chemical processes, avoiding product quality failures and production accidents caused by water quality issues.

Sterilization of Medical Devices

Hospitals and healthcare facilities place high demands on the sterilization of medical devices to ensure patient safety. Mixed bed resins play an important role in the sterilization of medical devices.

Sterilization Water: Producing deionized water for medical device sterilization effectively removes bacteria, viruses and other microorganisms from the water to ensure the effectiveness of the sterilization process.

Hygiene Compliance: The use of high purity water prepared from mixed bed resins for the cleaning and sterilization of medical devices helps hospitals and healthcare facilities meet strict hygiene codes and standards, safeguarding patient health and safety.

Metal Plating and Surface Treatment

In the metal plating and surface treatment industry, water quality has a significant impact on plating results and metal surface quality. Mixed bed resins play a key role in this industry.

Plating Process: Providing deionized water for the plating process ensures the stability and consistency of the plating solution, resulting in a uniform, dense coating on the metal surface and improving the quality and aesthetics of plated products.

Surface Cleaning: Before treating metal surfaces, cleaning with water treated with mixed bed resin can effectively remove oil, impurities and ions from metal surfaces, preventing defects from occurring during subsequent treatments and improving the quality and performance of metal surfaces.

Aquariums and Marine Systems

For aquariums and marine systems, maintaining good water quality is critical to the health of aquatic life. Mixed bed resins also have important applications in this area.

Water Simulation: In saltwater aquariums, deionized water prepared with mixed-bed resins can better simulate the marine environment and provide the right conditions for aquatic life. By removing harmful ions and impurities from the water, irritation and damage to aquatic organisms can be reduced, promoting their growth and reproduction.

Algae Control: Mixed Bed Resin can effectively prevent algae growth and mineral buildup in the tank, keeping the water clear and clean. This not only helps to improve aquarium viewing, but also creates a healthy living environment for aquatic life.

Residential and Commercial Water Purification

In addition to its wide range of applications in industry, mixed bed resins also play an important role in residential and commercial water purification.

Domestic Water: In the home, mixed bed resins can be installed in water purification systems to treat drinking and cooking water. By removing impurities and ions from the water, the taste and quality of the water can be improved, safeguarding the health of family members.

Commercial Applications: In the car wash industry and other commercial places, the water treated with mixed bed resin can avoid water stains caused by minerals in the water, and improve the cleaning effect of the car wash and the aesthetics of the vehicle.

Advantages Of Using Mixed-Bed Resin

Higher Purity: Mixed-bed resin has excellent deionization ability, can effectively remove almost all the dissolved ions in the water, and the output of ultrapure water is suitable for critical applications that require very high water quality, such as electronics manufacturing, pharmaceuticals and other industries.

Efficient Ion Removal: Unlike cation and anion beds alone, mixed-bed resins can remove both cations and anions from water in a single step, greatly improving the efficiency of ion removal, as well as being more compact, saving space and equipment costs.

Polishing Capability: As the final polishing step in the water treatment process, mixed bed resins are able to further purify water that has already been treated by other methods, removing residual trace ions and ensuring that the water quality reaches the highest purity standards.

Stabilization Of Water Quality: The unifying effect of mixed-bed resins ensures the production of stable, high-purity water, which is critical for processes and equipment that are sensitive to variations in water quality, and can effectively improve the stability of production and product quality.

Conclusion

Mixed-bed resins, with their unique properties and wide range of applications, have become an important safeguard for realizing high-purity water in a wide range of industries. From power production to electronics manufacturing, from the pharmaceutical industry to daily life water, mixed bed resin plays an irreplaceable role. As the water quality requirements of various industries continue to improve, mixed bed resins will continue to play an important role in maintaining high purity water standards in the future. Whether you are a business or an individual needing to address water quality issues, exploring products and solutions related to mixed bed resins would be a wise choice.

The article has been completed as requested and covers many aspects of mixed bed resins. You are welcome to speak to me at any time if you have changes to the content presentation, case studies, etc.

.png)