Ultra-pure water (UPW) has become an essential production factor in the booming micro- and nanoelectronics industry. Whether in the manufacture of computer processors, memory chips, LEDs, LCDs or photovoltaic modules, ultrapure water plays a vital role in complex wet chemical processes such as wafer processing and lithography.

Even in the field of microsystems technology, ultrapure water is indispensable for the manufacture of micro-mechanical components such as micro-pumps, micro-motors and micro-valves. Its importance lies in its ability to prevent or remove deposits and impurities on nanoscale fine structures, avoiding production failures and reducing failure rates. As electronics continue to move to smaller sizes, the quality of ultrapure water is becoming more demanding.

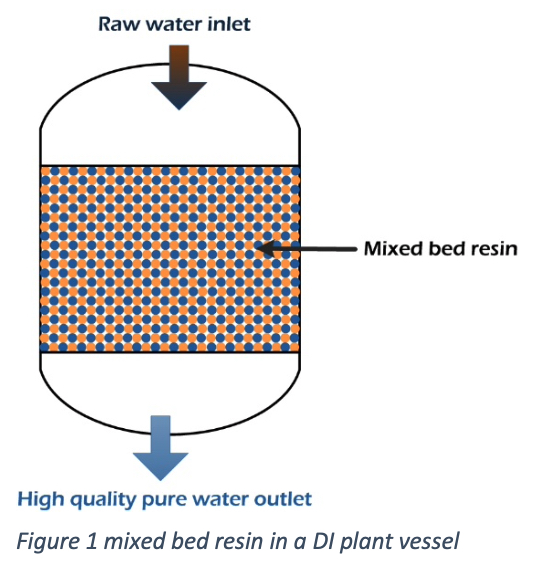

Mixed Bed (DI) Resin Grades, an ion exchange resin designed specifically for the nuclear and semiconductor industries, is at the heart of ensuring the high quality of ultrapure water production.

Mixed Bed (Di) Resin Grades: The Core Technology For Ultrapure Water Production

How It Works

Mixed Bed (DI) Resin Grades, or Mixed Bed Deionization Resins, is a specialized type of ion exchange resin. Its working principle is based on an ion exchange reaction. Various ionic impurities in the water are exchanged with the active ions on the resin and thus removed, ultimately producing high purity water. In simple terms, it is like “moving” the impurities in the water, transferring them from the water to the resin to achieve water purification.

Key Position In Ultrapure Water Production

Mixed Bed (DI) Resin Grades are at the center of the ultrapure water production process. From the initial treatment of the raw water, through the intermediate stages of further purification, to the final output of ultrapure water, the Mixed Bed Resin plays a decisive role. It is a key step in ensuring that the water quality meets the stringent standards of the nuclear and semiconductor industries, and has a direct impact on the stability of the entire production process and product quality.

Nuclear Grade Mixed Bed (DI) Resin Grades

.jpg)

Superior Performance Characteristics

Nuclear grade mixed bed deionization resins have a unique composition ratio, typically a 2:3 mix of hydrogen-based strong acid cations and hydroxide type I strong base anions. This special ratio gives it powerful properties.

First, its high resistivity effectively reduces the amount of conductive ions in the water, making the treated water virtually non-conductive. Secondly, its high capacity allows it to adsorb more impurity ions and reduce the frequency of replacement. Further, the long service life also reduces the operating costs in the nuclear industry. During the manufacturing process, precise specifications are followed to ensure high regeneration conversion of the resin and strict control of particle size. Nrw 3240 resin, for example, produces ultrapure water with resistivity as high as 18.3 megohms and conductivity as low as 0.055 microsiemens per centimeter, which is extremely pure.

Wide Range Of Nuclear Applications

Nuclear grade mixed bed resins are used in a wide range of applications in the nuclear industry.

Condensate polishing: During the operation of nuclear power plants, the water after steam condensation needs to be polished. Nuclear grade resin can effectively remove the residual trace impurities in the condensate to ensure the purity of the water, so that the water can be safely recycled to maintain the stable operation of the nuclear power plant.

Reactor water purification: The stability of water quality in the reactor is of utmost importance. Nuclear grade resins continuously purify the reactor water, removing impurities and radioactive substances generated by the nuclear reaction to ensure the safe and efficient conduct of nuclear reactions.

First circuit water treatment: In the first circuit systems of Pressurized Water Reactors (PWR) and Boiling Water Reactors (BWR), nuclear grade resins prevent impurities in the water from corroding piping and equipment, extend the service life of nuclear power plant equipment, and reduce maintenance costs and safety risks.

Wastewater treatment: For wastewater contaminated by radiation, nuclear grade resins can effectively remove the radioactive substances in the wastewater, so that the wastewater can meet the safe discharge standards, and protect the ecological environment and the health of personnel.

Semiconductor Grade Mixed Bed (DI) Resin Grades

Unique Performance Advantages

Semiconductor grade mixed bed deionization resins have the same outstanding performance. It also has a high resistivity, typically up to 18+ megohms, a high capacity, and a similar composition to the nuclear grade, which is a 2:3 mix of Strong Acid Cation (SAC) and Strong Base Anion Type I (SBA) resins. The appearance of the resin is small black spherical particles with a gel structure. This special structure makes it stable in any pH range, reducing impurities in the water to extremely low levels, and meeting the demanding water quality requirements of semiconductor manufacturing.

An Important Application in Semiconductor Manufacturing

Semiconductor grade mixed bed resins are indispensable in the semiconductor manufacturing industry.

Device manufacturing: In the manufacturing process of semiconductor devices such as chips, ultrapure water is used in several key process steps such as cleaning and etching. Ultrapure water produced by semiconductor-grade resins can effectively prevent impurities from contaminating the device, ensure the performance and quality of the device, and improve the yield rate of the product.

Equipment cooling: Semiconductor manufacturing equipment generates a large amount of heat during operation, requiring water for cooling. Ultrapure water treated with semiconductor-grade resin will not affect the cooling effect due to impurity deposition, ensuring stable operating temperature of the equipment, avoiding malfunction due to overheating of the equipment, and improving production efficiency.

Surface cleaning: The cleanliness of semiconductor device surfaces is critical to subsequent processes and product performance. Ultrapure water can be used to clean the surface of the device to remove dust, oil and other impurities. Ultrapure water produced from semiconductor grade resins ensures that the surface is cleaned thoroughly, providing a good foundation for subsequent processes such as coating and encapsulation.

Key Considerations for Selecting Mixed Bed (DI) Resin Grades

Resin Capacity

Resin capacity is one of the primary considerations when selecting Mixed Bed (DI) Resin Grades. Different production sizes and water qualities require different resin capacities. If you are treating large volumes of water with high impurity levels, you will need to select a resin with a high capacity to ensure efficient treatment and to minimize the frequency of resin changes, thus reducing operating costs.

Resistivity

Resistivity directly reflects the purity of water, different industries and processes have clear requirements for water resistivity. The nuclear industry and semiconductor industry have extremely high requirements for resistivity, and when selecting resins, it is necessary to ensure that the resistivity of the ultrapure water produced meets the corresponding standards, otherwise it will affect the quality of production and equipment operation.

Chemical Stability

In practical applications, resins are exposed to a variety of chemicals and different acid and alkali environments. Therefore, chemical stability is crucial. Resins with good chemical stability can operate stably for a long time under different chemical environments, and are not easy to be damaged or failed, which reduces maintenance and replacement costs and improves the reliability of the production system.

Impurity Removal Capability

Water from different industries may contain different types of specific impurities. For example, nuclear industry wastewater may contain radioactive substances, semiconductor manufacturing water may contain trace metal ions. When selecting resins, you need to choose resins with targeted removal capabilities according to the impurity characteristics of the specific industry to ensure that the water quality meets the standards.

Product example: MR120 Electronic Grade Polishing Ion Exchange Resin

Wide Range Of Applications

MR120 Electronic Grade Polishing Ion Exchange Resin has a wide range of applications and can play an important role in the ultrapure water mixed-bed systems of many industries such as electronics, semiconductors, display, biochemical medicine, military, optical materials and photovoltaic.

Outstanding Product Characteristics

Appearance and ionic form: MR120 resin is yellowish brown spherical particles in appearance, and its ionic form is H+/OH-, which makes it able to effectively remove anionic and cationic impurities in water.

Performance parameters: It has high volumetric total exchange capacity, cation resin (H type) ≥ 0.6mmol/ml, anion resin (OH type) ≥ 0.45mmol/ml, and high regeneration degree. Its cation and anion resins excel in a number of parameters, such as total exchange capacity, particle size range, uniformity coefficient, etc., which ensures the high efficiency and stability of the resins.

Significant Product Advantages

MR120 resin ensures that treated water quality is fully compliant with service requirements, preventing corrosion of equipment and piping due to water quality issues. And it offers comparable performance to Purolite MB400, providing customers with a reliable and cost-effective option for improving the quality and efficiency of ultrapure water production and reducing production costs.

Conclusion

Mixed Bed (DI) Resin Grades play an irreplaceable role in the production of ultrapure water for the nuclear and semiconductor industries. Whether it is the important application of nuclear grade resins in various aspects of nuclear power plants, or the semiconductor grade resins to ensure the quality of semiconductor manufacturing, have highlighted its importance. At the same time, key factors such as resin capacity, resistivity, chemical stability and impurity removal capability need to be considered when selecting the right resin.

High-quality products like MR120 Electronic Grade Polishing Ion Exchange Resin provide a reliable solution for the industry. As technology continues to advance, we look forward to continued innovation in ion exchange resin technology, which will provide stronger support for the development of the nuclear and semiconductor industries, and propel the related industries to a higher quality stage of development.

.png)

.jpg)