Uranium, as an important energy resource, is widely used in nuclear power generation and other high-end technology fields. The efficiency of uranium mining directly affects the supply of uranium resources and the economic benefits of mining companies. In the uranium mining process, the choice of uranium extraction technology is crucial. In recent years, ion exchange resins have become one of the most widely used technologies in uranium mining due to their superior extraction performance and economic efficiency. This article will explore in depth the role and advantages of ion exchange resins in uranium mining and how to optimize their use.

What is An Ion Exchange Resin

Definition and Basic Principles of Ion Exchange Resins

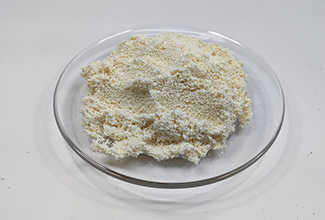

Ion exchange resins are highly selective synthetic polymers that selectively adsorb and release ions from a solution through ion exchange. In uranium mining, the core function of ion exchange resins is to extract uranium ions from uranium-containing solutions. This process typically occurs during the leaching stage of uranium ore, where the resin captures and concentrates uranium elements by exchanging uranium ions with those in the solution.

Types and Applications of Ion Exchange Resins

Ion exchange resins are classified into two types: cation exchange resins and anion exchange resins. Cation exchange resins are generally used for uranium extraction because uranium is a positively charged ion. During uranium extraction, the resin exchanges sodium or hydrogen ions from its surface, which then combine with uranium ions in the solution, thereby separating the uranium from the slurry.

The Key Role of Ion Exchange Resins In Uranium Extraction

The Core Role of Ion Exchange Resins in Uranium Mining

In uranium mining, uranium extraction is typically carried out through leaching. In this process, ion exchange resins play a crucial role. The leachate usually contains various metal ions, and ion exchange resins, by selectively adsorbing uranium ions, effectively separate uranium from these other metal ions. The high selectivity of the resin ensures efficient uranium recovery, significantly improving extraction efficiency.

Advantages of Ion Exchange

Compared with traditional solvent extraction methods, ion exchange methods have several advantages. First, ion exchange resins can achieve efficient uranium extraction at a relatively low cost. Second, the ion exchange process has high selectivity, effectively avoiding interference from other metal ions in the uranium extraction process, thus ensuring the purity and recovery rate of the uranium.

Advantages of Ion Exchange Resins in Uranium Recovery

High Selectivity and Efficient Extraction

The advantages of ion exchange resins in uranium mining cannot be ignored. First, ion exchange resins have extremely high selectivity, enabling them to precisely capture uranium ions while having almost no adsorption effect on other metal ions, which greatly improves the uranium recovery rate.

Cost-Effectiveness and Environmental Advantages

Secondly, the long-term use of ion exchange resins is highly economical. Although the initial investment may be high, the long service life of the resin and its ability to be regenerated and restored reduce the frequency of replacements and lower operating costs. Furthermore, ion exchange methods have a smaller environmental impact compared to other methods. In uranium mining, the use of ion exchange resins not only improves uranium recovery rates but also reduces the use and emission of harmful chemicals, meeting environmental protection requirements.

How to Optimize the Ion Exchange Process In Uranium Mining

Key Factors Affecting the Efficiency of Ion Exchange Resins

The efficiency of ion exchange resins depends not only on the properties of the resin itself but also on the operating conditions. To ensure optimal extraction results, operating parameters must be optimized. The following factors play a crucial role in optimization:

Flow Rate: Both excessively fast and slow flow rates affect ion exchange efficiency. Too fast a flow rate may result in insufficient contact time between the resin and the solution, while too slow a flow rate will reduce the overall system's processing capacity.

pH Value: Different ion exchange resins are suited to different pH ranges; therefore, controlling the pH value of the leachate is critical. Both excessively high and low pH values can lead to a decline in resin performance.

Temperature: Excessively high or low temperatures can affect the rate of ion exchange. Appropriate temperature conditions help accelerate the ion exchange reaction and improve uranium recovery.

Resin regeneration and maintenance

To maintain the long-term performance of ion exchange resins, regular regeneration is essential. Resin regeneration technology can restore the resin's exchange capacity, thereby reducing replacement frequency and lowering overall costs. Common methods during regeneration include acid washing and alkali washing, which aim to remove impurities from the resin surface and restore its effective adsorption capacity.

Challenges and Solutions for Uranium Extraction Using Ion Exchange Resins

Resin Contamination and Scale Buildup Problems

The slurry may contain high concentrations of other substances that can contaminate the resin surface, thereby affecting ion exchange efficiency. The solution is to regularly clean the resin or use pretreatment techniques to reduce contamination.

Resin Lifespan and Replacement Issues

Resins gradually degrade during long-term use, leading to a decrease in their adsorption capacity. To address this issue, companies need to regularly check the condition of the resin and replace or regenerate it in a timely manner.

Impacts and Countermeasures of Resin Degradation

Resin degradation can be related to operating conditions (such as temperature and pH). By precisely controlling operating parameters, resin degradation can be minimized and its service life extended.

The Impact of Ion Exchange Resins on The Economic Benefits of Uranium Mining

Cost-Effectiveness of Ion Exchange Resins

The application of ion exchange resins in uranium mining has not only improved uranium recovery rates but also brought considerable economic benefits. Although the initial purchase cost of ion exchange resins is high, their long-term high efficiency and low maintenance costs enable companies to achieve cost savings in long-term operation.

Comparison with Other Extraction Methods

Compared with other extraction technologies such as solvent extraction, ion exchange has the advantages of high selectivity, low operating cost and environmental friendliness, making it an economical and sustainable technology option for large-scale uranium mining.

Conclusion

Ion exchange resins play a crucial role in uranium mining. They not only improve uranium recovery and extraction efficiency but also offer excellent environmental and economic benefits. Despite some challenges in their application, ion exchange resins remain one of the most advantageous uranium extraction technologies currently available, thanks to optimized operating parameters and regular maintenance.

The continued development and application of ion exchange technology will ensure the efficient recovery of uranium resources, bringing greater economic and environmental benefits to the global uranium mining industry.