-

202026-01

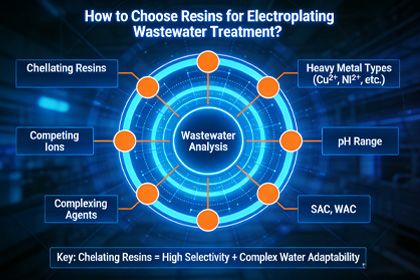

How to Choose Resins for Electroplating Wastewater Treatment?Chelating resins deliver ppb-level heavy metal removal and high-value metal recovery for electroplating compliance.View More >1

How to Choose Resins for Electroplating Wastewater Treatment?Chelating resins deliver ppb-level heavy metal removal and high-value metal recovery for electroplating compliance.View More >1 -

132026-01

Navigating Uranium Extraction: Matching Ion Exchange Resins with Ore Process FlowsProcess Flow of Different Uranium Ores: Why Resin Selection is a Systematic Engineering Project.View More >9

Navigating Uranium Extraction: Matching Ion Exchange Resins with Ore Process FlowsProcess Flow of Different Uranium Ores: Why Resin Selection is a Systematic Engineering Project.View More >9 -

042026-01

Gel-type Resins VS Macroporous resins: Complete ComparisonGel resin vs. macroporous resin deep comparison: exchange capacity, fouling resistance, kinetics, and osmotic shock. Expert guide to choosing the right type.View More >15

Gel-type Resins VS Macroporous resins: Complete ComparisonGel resin vs. macroporous resin deep comparison: exchange capacity, fouling resistance, kinetics, and osmotic shock. Expert guide to choosing the right type.View More >15 -

232025-12

Ion Exchange Resin Dehydration Treatment MethodIon exchange resin dehydration causes cracking and capacity loss. Learn proper saline rehydration steps and storage practices.View More >14

Ion Exchange Resin Dehydration Treatment MethodIon exchange resin dehydration causes cracking and capacity loss. Learn proper saline rehydration steps and storage practices.View More >14 -

092025-12

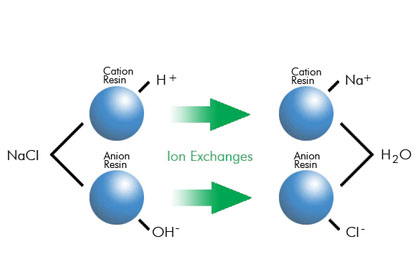

Why Ion Exchange Resins Require Pretreatment Before UseIon exchange resin pretreatment ensures clean startup, stable water quality, and maximum performance for industrial and ultrapure water systems.View More >38

Why Ion Exchange Resins Require Pretreatment Before UseIon exchange resin pretreatment ensures clean startup, stable water quality, and maximum performance for industrial and ultrapure water systems.View More >38 -

012025-12

What are The Main Causes of Ion Exchange Resin Breakage?Ion exchange resin breakage explained: understand key causes, physical and chemical mechanisms, and practical prevention strategies to improve system performance and extend resin lifespan.View More >11

What are The Main Causes of Ion Exchange Resin Breakage?Ion exchange resin breakage explained: understand key causes, physical and chemical mechanisms, and practical prevention strategies to improve system performance and extend resin lifespan.View More >11